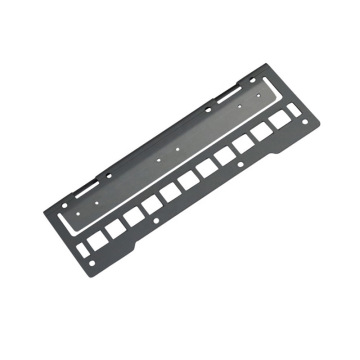

Stainless steel can be punched. Modern metal punching is carried out by using heavy machinery to create holes and indents in a piece of metal. The principle is relatively simple. The sheet metal material being punched is sandwiched between the punch and a mold.

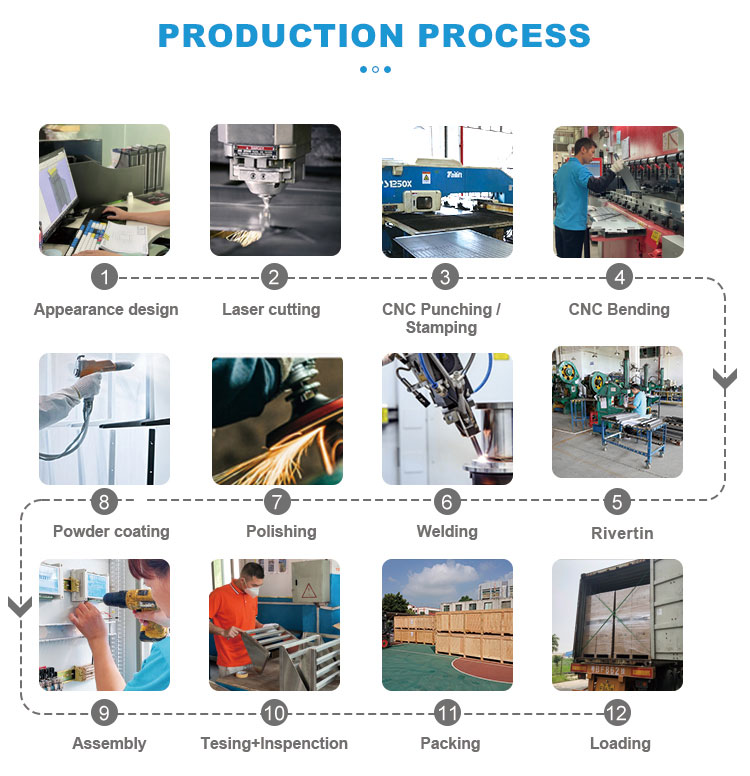

DONGJI is the sheet metal fabricator with ISO, CE, SGS, BV and TUV certificates with 12 years history to oem customize different kinds of sheet metal cabinets. Full production line like Laser cutting, CNC cutting and bending, Welding, and powder coat surface treatment with perfect quality control system. OEM orders of metal cabinets are welcome, we could support you high standard quality and compectitive price.

Our service and our main products

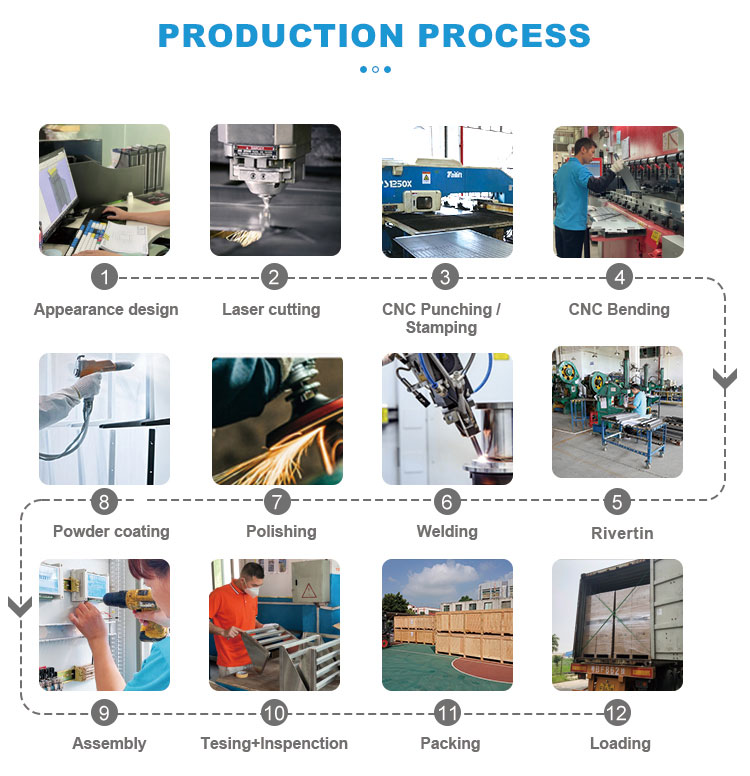

Our service including laser cutting, CNC punch press, metal bending, steel welding, stainless steel automatic welding line, enclosure foaming, surface powder coating spraying ,assembly ,testing and so on.

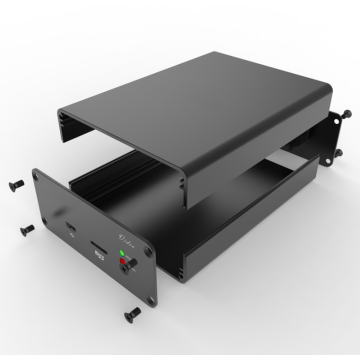

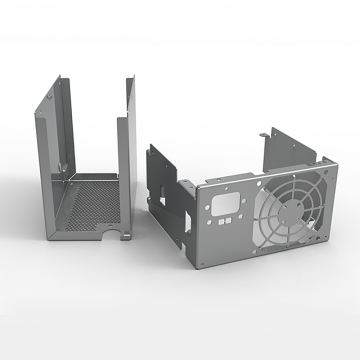

Our main products are in customized sheet metal fabrication, which can make different kinds of sheet metal products-metal enclosures, metal cabinets,metal housings as per customers' drawing.

OEM one stop sheet metal solution are Provided.

Products Description

|

-

Material: Stainless steel or Custom

-

Dimensions: Custom

-

Application: Commercial and residential use

-

Craftsmanship: Laser steel cutting, CNC steel punching, CNC steel bending, CO2 welding, surface finishing, assembly

-

Surface finishing: Brushing, Polishing or Custom

|

Materials used - Customized :

* Aluminum, Steel, Stainless Steel 201 or 304, Galvanized, Copper

* Material thickness ranges from 0.2mm-30mm depending on material

* RoHS compliance for some materials

* Material Certifications available upon customoers' request

Finishing - Customized :

* Powder coating, painting, plating, anodizing, polishing, Sandblasting, etc.

Custom sheet metal designs are welcome!

Fabricaition Service

Ausrüstungsliste

|

Laser cutting machines

(3 Sets)

|

Power: 6000W/3000W/2000W

Max operation thickness: 0.5-25mm

Max operation length: 6000mm

Tolerance: ±0.1mm

Cutting Speed: 10000mm/min (based on 1mm thickness)

|

CNC punching machines

(2 Sets)

|

Punching capacity: 30T

Tolerance:±0.1mm

Punching speed: 800 times/min (based on 1mm thickness)

|

CNC bending machines

(12 Sets)

|

Bending capacity: 100T

Max operation thickness: 30mm

Tolerance: 0.1mm

Max operation length: 3200mm

|

Mold punching machines

(8 Sets)

|

Punching capacity: 125T

Punching with dedicated tooling to assure tolerance

High efficiency for mass production

|

Welding

(30 Stations)

|

TIG welding, GMAW, Laser welding

Can be applied to different thickness sheet metal

Stable and high efficiency

|

Polishing machines

(6 Sets)

|

Keep the material bright and good luster

8K mirror surface

|

Powder coating

(1 production line)

|

Environmental friendly standard line

Automatic production line

Anti-rust and corrosion-resistant

5 years quailty assurance

|

Assembly

(2 production lines)

|

Inner electronic components assembly

Complete machine assembly

Smart system installation

|

|

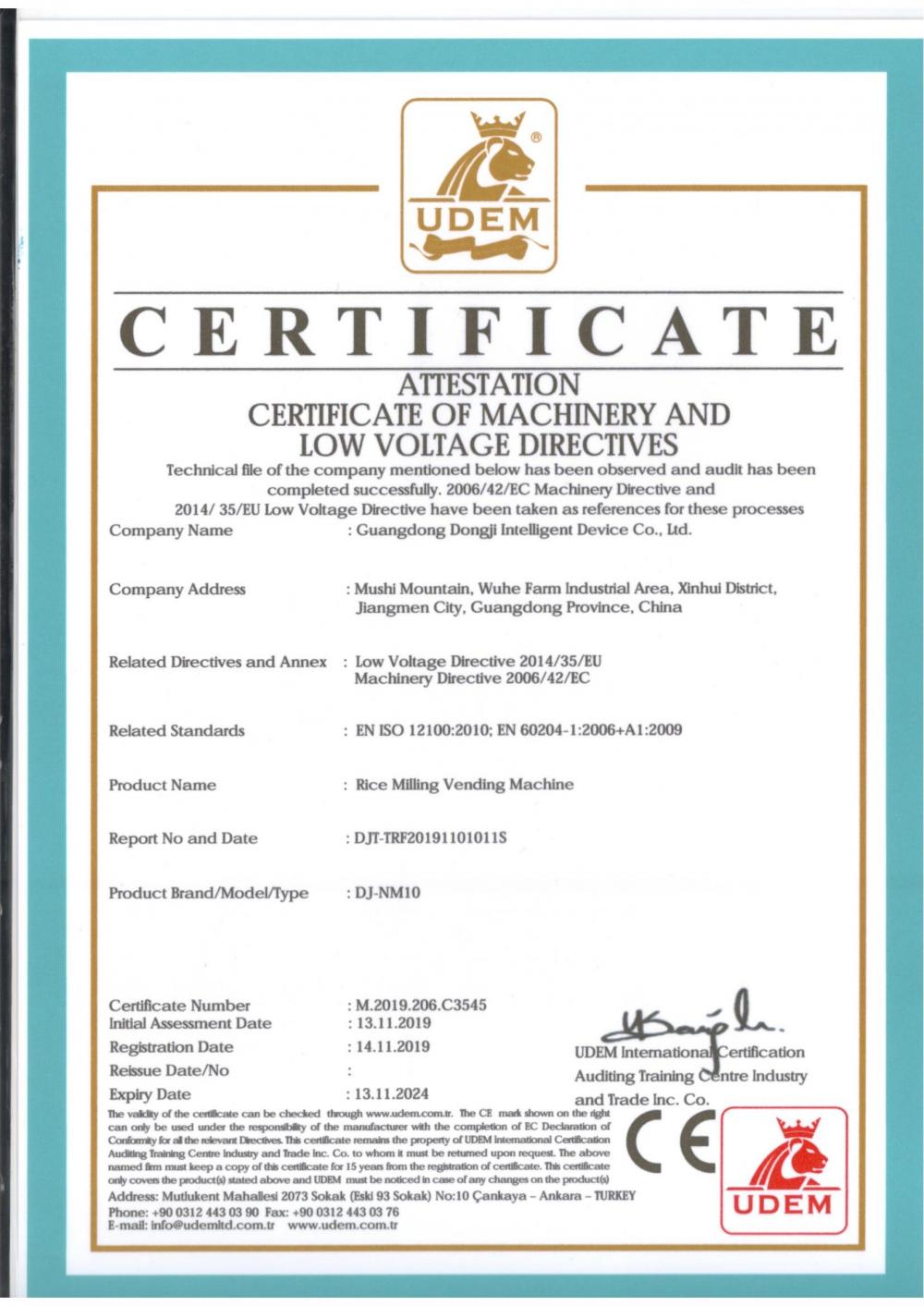

Our Certificates & Our Partner

FAQ - Why Choose Us?

Q1: Are you a sheet metal fabrication Comprehensive service provider?

We are an ISO 9001 certified factory specialized in sheet metal fabrication Comprehensive service provider.

Q2: Does Dongji have any certifications?

We have ISO 9001, CE, SGS, UL and TUV Certifications.

Q3: What services does DongJi offer?

Our services include sheet metal product laser cutting, punching, bending, welding, stamping, finishing, assembly, testing and so on.

We have experience in work fabrication for a variety of metals such as Stainless Steel, Aluminum, carbon Steel, Cold Rolled Steel, High Carbon Steel, Hot Rolled Steel.

Q4: Does Dongji provide design and engineering?

DongJi specializes in design and engineering. We can work with you from start to finish on any product you are creating.

Q5: Can Dongji assist to do assemble and testing for products?

Dongji can assist you in assembling any type of product. We have 12 years of experience in R&D, production assembly and testing of smart devices. Our engineering R&D team includes electronic engineers, circuit control engineers, software engineers, test engineers, etc.

We are confident that we can assist you with the assembly and testing of any project.

Q6: How long should we take for a quotation?

After receiving detailed information (your 2D/3D drawings or samples), we will quote you within 3 days.

Q7: How about the lead time?

General speaking, 15 days for sample, 30 days for mass production. If you have any request, please contact with us.

Welcome to sent us your design so that we can quote you the price base on your design.

Contact: Carmen Huang